High-Density Polyethylene (HDPE) pipe production line is an advanced manufacturing setup designed for the efficient production of HDPE pipes. HDPE pipes are known for their exceptional durability, flexibility, and corrosion resistance, making them widely used in various industries for transporting fluids and gases.

HDPE pipe production line is highly automated and operates continuously to ensure efficiency and precision in manufacturing. It's capable of producing pipes of various sizes and specifications to cater to diverse industrial, agricultural, municipal, and residential needs.

The machine host extruder using the special treatment single screw extruder, and the forming product is good.

This series HDPE pipe production line is mainly used for producing pipe of water supply and drainage in the field of agriculture and construction, cable and ect.

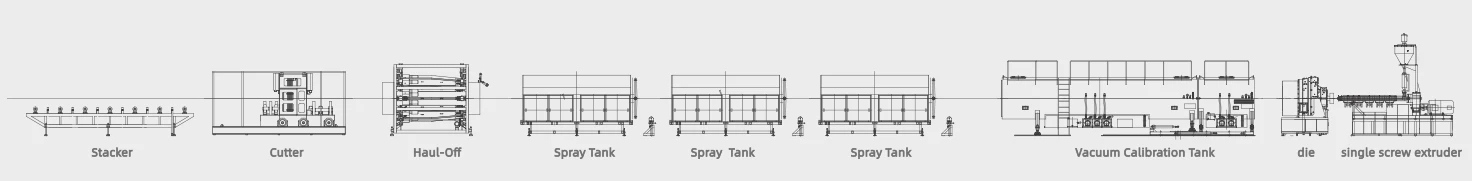

This HDPE pipe extrusion machine group consist of vacuum calibration tank, haul-off unit, cutting unit, stacker and so on.

The machine units can adopt the single screw co-extruder for extrusion.

The production pipe diameter range: Φ20-Φ2000mm

The extrusion line adopt the electrical system: ABB speed governor, Japanese RKC temperature controller, SIMENS contactor.

HDPE pipe extrusion machines serve various industries and sectors, including:

Water Supply and Distribution: HDPE pipes are widely utilized for water supply networks in municipal, residential, and industrial areas due to their durability, corrosion resistance, and flexibility, making them ideal for transporting potable water over long distances and diverse terrain.

Sewage and Drainage Systems: HDPE pipes are commonly used in sewage and drainage systems because of their resistance to chemicals, abrasion, and corrosion. They effectively convey wastewater, stormwater, and sewage to treatment plants or disposal sites, contributing to efficient waste management.

Gas Distribution: HDPE pipes find extensive use in distributing natural gas and other combustible gases in residential, commercial, and industrial settings. Their lightweight design, ease of installation, and corrosion resistance make them a preferred choice for gas distribution networks.

Irrigation and Agriculture: HDPE pipes are employed in irrigation systems for agricultural purposes, including crop irrigation, drip irrigation, and sprinkler systems. Their flexibility, durability, and UV resistance enable them to withstand harsh outdoor conditions and facilitate efficient water distribution to crops.

The HDPE pipe extrusion line consists of several key components, each playing a critical role in the efficient production of HDPE pipes:

Hopper – The starting point where raw HDPE pellets are introduced into the system.

Extruder – The core component where HDPE pellets are melted. It consists mainly of a barrel, screw, and heater.

Die Head – Attached to the extruder, it shapes the molten HDPE into a pipe form.

Vacuum Tank – Stabilizes the pipe shape using a vacuum system and cools it down to solidify its form.

Cooling Tank – Further cools the pipe to ensure strength and dimensional stability.

Haul-Off – Pulls the pipe through the line at a consistent speed to maintain uniform thickness and diameter.

Cutter – Precisely cuts the pipes to desired lengths.

The single screw extruder plays a fundamental role in HDPE pipe production, operating on a relatively straightforward principle. Here’s a detailed breakdown:

Feeding – HDPE pellets are fed into the extruder’s hopper, moving down the barrel due to gravity.

Melting – The pellets enter the barrel, where they encounter the rotating screw. Friction and heating elements along the barrel gradually melt the pellets.

Mixing and Homogenizing – The screw, designed with precise geometries for mixing, ensures the melted HDPE is consistently homogeneous.

Extruding – The now molten HDPE is forced through the die head at the end of the barrel, shaping it into a pipe.

Cooling and Solidification – The extruded pipe passes through the vacuum and cooling tanks, solidifying into its final form.

This process, facilitated by the single screw extruder, allows for the efficient production of high-quality HDPE pipes. Each component plays a specific role, ensuring the end product meets the requirements for various applications.

| Pipe Diameter(mm) | Extruder Model | Downstream Model | Vacuum Calibration Tank | Spraying Cooling Tank | Hauler | Cutter |

| 16-63 | SJ-50/36 | GF-63 | 6000mm | 6000mm*2 | 2 Caterpillars | Non-dust Cutter |

| 20-110 | S)-60/36 | GF-110 | 6000mm | 6000mm*2 | 3 Caterpillars | |

| 50-160 | SJ-60/36 | GF-160 | 6000mm | 6000mm*2 | 3 Caterpillars | |

| 75-250 | S)-75/36 | GF-250 | 8000mm | 6000mm*2. | 4 Caterpillars | |

| 90-315 | S1-75/36 | GF-315 | 8000mm | 6000mm*2 | 4 Caterpillars | |

| 160-450 | SJ-90/36 | GF-450 | 11000mm | 6000mm*2 | 6 Caterpillars | |

| 315-630 | SJ-120/36 | GF-630 | 11000mm | 6000mm*3 | 8 Caterpillars | |

| 355-800 | SJ-120/36 | GF-800 | 1500+10500mm | 6000mm*3 | 8 Caterpillars | |

| 630-1200 | SJ-150/36 | GF- 1200 | 1500+10500mm | 6000mm*3 | 8 Caterilars |

Raw Material Handling: The process begins with the handling and preparation of raw materials, which usually involves high-quality HDPE resin pellets. These pellets are fed into the production line machinery.

Extrusion Process: The heart of the production line is the extrusion process. Here, the HDPE resin pellets are heated and melted in an extruder, forming a molten plastic. The molten plastic is then forced through a die, giving it the desired shape and size of the pipe.

Cooling and Sizing: Once the molten plastic is shaped, it passes through a cooling system, where it solidifies and takes the form of a pipe. Sizing tools ensure the pipe meets the required dimensions and specifications.

Cutting and Stacking: The continuous pipe produced is cut into specific lengths as per requirements. These cut pipes are then stacked or coiled for packaging and transportation.

Quality Control: Throughout the production process, quality control measures are implemented to ensure that the pipes meet industry standards and specifications. This includes monitoring dimensions, wall thickness, strength, and other critical parameters.

Optional Additional Processes: Depending on the intended application, additional processes like printing, marking, or surface treatment might be included in the production line.

The HDPE pipe production line is highly automated and operates continuously to ensure efficiency and precision in manufacturing. It's capable of producing pipes of various sizes and specifications to cater to diverse industrial, agricultural, municipal, and residential needs.

The final pipes manufactured through this line exhibit excellent properties such as resistance to corrosion, chemicals, abrasion, and impact, making them ideal for applications in water supply, gas distribution, drainage systems, and more.

Here are several advantages of using an HDPE pipe extrusion line:

Versatility: HDPE pipes can be produced in a wide range of sizes and thicknesses, making them suitable for various applications such as water supply, drainage systems, gas distribution, and industrial piping.

Durability: HDPE pipes have excellent resistance to corrosion, chemicals, and abrasion, making them highly durable and long-lasting. They can withstand harsh environmental conditions and have a long service life.

Flexibility: HDPE pipes have a high level of flexibility, allowing them to withstand ground movements and seismic activities without cracking or breaking. This flexibility also simplifies installation, especially in areas with challenging terrain.

Cost-effective: HDPE pipes offer cost advantages over other materials due to their lower installation and maintenance costs. They require minimal maintenance, have a long lifespan, and are resistant to corrosion, reducing the need for repairs or replacements.

Environmentally Friendly: HDPE pipes are recyclable and have a low carbon footprint. They are made from non-toxic materials and do not release harmful substances into the environment during production or use.

Overall, the use of an HDPE pipe extrusion line provides numerous benefits in terms of performance, cost-effectiveness, and sustainability.

HDPE pipes are manufactured by melting the HDPE resin and other additives in an extruder, then shaping and cooling the material.

HDPE pipes should meet applicable standards such as ISO 4427, DIN 8074, and EN 12201.

An HDPE pipe extrusion line works by melting and shaping high-density polyethylene (HDPE) material into pipes of various sizes and thicknesses. Here is a step-by-step explanation of how it works:

1. Material Feeding

2. Melting and Homogenization

3. Extrusion and Shaping

4. Cooling and Solidification

5. Haul-off and Cutting

6. Stacking and Packaging

Throughout the process, various parameters such as temperature, pressure, and speed are carefully controlled to ensure the quality and consistency of the produced HDPE pipes.

Extrusion Machine: The heart of the production line, this machine melts and extrudes the HDPE resin through a die to form the pipe's shape and size. The extruder heats and melts the HDPE pellets, which are then pushed through a die head to create the pipe's desired diameter and thickness.

Pipe Cooling System: After extrusion, the pipes need to be rapidly cooled to solidify the material and maintain its shape. Cooling tanks or water spray systems are used for this purpose.

Pipe Sizing and Shaping Equipment: This part of the line ensures that the pipes are accurately sized and shaped according to the required specifications. Sizing sleeves or vacuum sizing systems help to achieve the desired diameter and shape.

Haul-off or Puller: This component pulls the newly formed pipe through the production line at a consistent speed, maintaining the proper tension and preventing deformities.

Cutting and Stacking Equipment: Once the pipes have been extruded to the desired length, they are cut to size and stacked or coiled for storage or further processing.

Quality Control and Inspection: Various sensors, gauges, and inspection systems are incorporated along the production line to monitor the quality and dimensions of the pipes continuously.

The capacity or output of the HDPE pipe extrusion line offered by QING CHEN YU can range from 80kg/h to 1000kg/h. However, it is important to note that the specific capacity may vary depending on factors such as the size and specifications of the pipes being produced, the speed of the extrusion line, and the efficiency of the equipment. It is recommended to consult with the manufacturer or supplier for precise details regarding the capacity of a specific HDPE pipe extrusion line.

The HDPE pipes produced by an extrusion line can be used in various applications, including:

Water Supply

Gas Distribution

Drainage Systems

Industrial Piping

Geothermal Systems

Landfill and Environmental Protection

Cable Protection

It is important to note that the specific applications of HDPE pipes can vary depending on factors such as the pipe size, thickness, and specific requirements of the project.

HDPE pipes are strong, durable, and safe for use in a variety of applications. They are also resistant to chemicals and abrasion, making them ideal for infrastructure projects.

E-mail:

Tel:

Address:

Building A, Sanxing Industrial Zone, Zhangjiagang City, Jiangsu Prov, China