A double shaft shredder is a type of shredder machine that is equipped with two parallel shafts, each fitted with rotary blades. The blades rotate in opposite directions to shred materials such as plastics, rubber, wood, and metal into small, manageable pieces. The shredder is used in various industries, including recycling, waste management, and manufacturing, to reduce the size and volume of waste materials for easier transportation and disposal.

XJG-D Double-shaft shredder/crusher can shred all kinds of soft plastics and rubbers like, plastic film, greenhouse film, fishing nets, plastic bags, ton bags/ jumbo bags, woven bags, nonwoven bags, nonwoven fabric, tires, etc.

HS Code: 84778000.

Low rotation rate.

Low noise and high torque.

Electrical overloading protective.

Blade hardness at 60-65 by SKD11.

Hydraulic system, an independent power system, the structure solid, smooth running, feed material easily, high output.

PLC program control system automatically rotates, stops and realizes fully automatic operation of equipment. Safe and reliable running.

Model | XJG-D600 | XJG-D800 | XJG-D1000 | XJG-D1200 | XJG-D1600 | XJG-D2000 |

Number of Rotary blades | 60 | 78 | 96 | 114 | 156 | 192 |

Shaft rotary speed(r/min) | 65r/min | 65r/min | 60r/min | 60r/min | 60r/min | 60r/min |

NO. of Fixed blades | 4 | 4 | 8 | 8 | 8 | 8 |

Shaft diameter(mm) | 255 | 255 | 300 | 300 | 350 | 500 |

Size of hopper opening(mm) | 1600*1400 | 1600*1400 | 1600*1500 | 1600*1500 | 1800*1600 | 2300*2100 |

Motor power (kw) | 22*2 | 30*2 | 37*2 | 45*2 | 55*2 | 75*2 |

Shredder Capacity (kg/h) | 600-800 | 800-1000 | 1000-1200 | 1200-1400 | 1600-1800 | 2000-2200 |

Machine size(m) | 3.30*1.40*2.2 | 3.4*1.4*2.25 | 3.6*1.50*2.35 | 3.8*1.50*2.45 | 4.8*1.6*2.45 | 5.2*2.1*2.45 |

Machine weight(kg) | 4500 | 5200 | 6000 | 6400 | 7500 | 8600 |

*As a professional plastic recycling machine company in China, we also have custom dual-shaft shredders for sale. Feel free to contact us for further info!

Double shaft shredders offer several environmental benefits in waste reduction. By shredding waste into smaller sizes, these machines reduce the volume of waste and make it easier to transport. This, in turn, reduces emissions from transportation and landfilling. Additionally, the shredded materials can be reused for manufacturing new products, thereby reducing the need for virgin raw materials, which can be resource-intensive to extract. Finally, the use of double shaft shredders supports the circular economy by promoting the reuse of resources, minimizing waste generation, and reducing environmental impacts associated with waste disposal.

1. Structurer Difference

Double shaft shredder is mainly composed of

· feed hopper

· two shredded spindles

· shredding blades

· discharge hopper

Single shaft shredder is mainly composed of

· feed hopper

· stationary cutter

· shredding blades

· Screen

2. Blade Type Differences

Single shaft plastic shredder only has one rotary shaft holding all the cutting blades. When the shaft rotates, carrying the cutting blades, there’s a shearing force between the rotating blades and the stationary cutter.

Double shaft shredder has two rotary shafts, both hold many blades. The two shafts rotate relative to each other to cutting materials.

3. Different Materials To Be Cutted

Double Shaft Shredder features high torque and high efficiency, suitable for shredding domestic waste, industrial waste, electronic waste, biomass waste, kitchen waste, medical waste, wood chips, and other materials, etc.

Single shaft shredder is commonly used in paper mill processing waste fabric, leather scrap, domestic waste, PE, PP, plastic pipe, plastic film, woven bags, wire and cable cans, aluminum scrap, and other aluminum products.

Double-shaft shredder, also known as double-shaft shredder, shearing design principle, alloy knife material, through shearing, tearing, and extrusion to reduce the size of the material. Strong impact resistance, broken metal knives do not break.

The double shaft shredder is mainly used in domestic waste, industrial waste, and leather scraps, organic waste, medical waste, RDF, hazardous waste, bulky waste, paper mill twisted rope, etc.

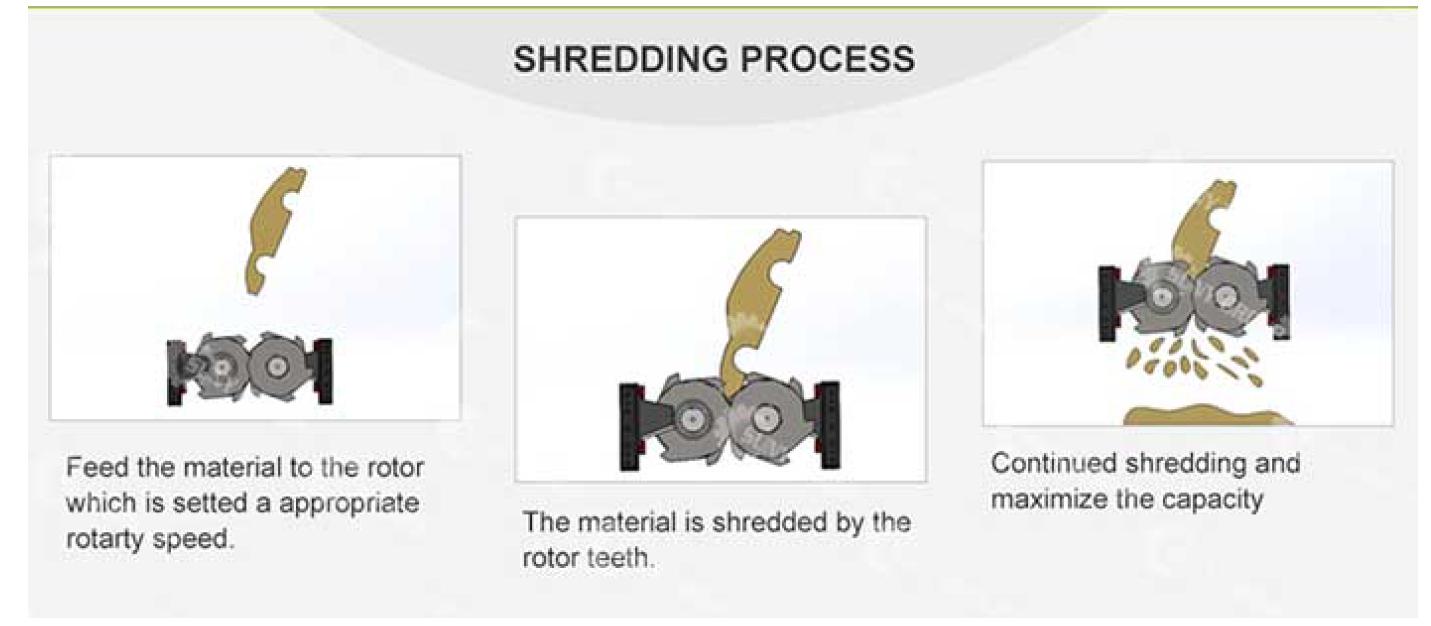

The working principle of the double-shaft shredder: During the crushing process, the claws on the rotor pull the material into the crushing cavity. The blades are arranged in a staggered and occlusal manner so that the material can be cut and broken in both the horizontal and vertical directions at the same time. After the material is broken, it is intercepted and peeled off by the partition and finally discharged downward.

The main working part of the crusher is a pair of relatively rotating rollers, and the rollers are equipped with gear teeth arranged in a spiral. After the material enters the machine, it is bitten and sheared by the gear teeth made of staggered high-hardness wear-resistant materials, and is split, broken and pulverized to a size lower than the set size, and then forced to be excluded from the machine. The roller is driven by the motor through the reducer and has a large torque. When encountering difficult-to-break objects, it will automatically reverse under the action of the PLC automatic control system, and rotate forward and reverse many times until the materials are broken and discharged. This principle equipment has different names in various industries: metal shredder, coal grading crusher, domestic waste shredder, construction waste shredder. According to its own structural characteristics, it can be called a spiral-toothed roller crusher (shredder), which is commonly used in the form of double shaft (double toothed roller), as well as single shaft and four shafts (four-toothed roller).

Plastics, rubber, wood, paper, cardboard, metal, and electrical trash are just a few of the things that a twin shaft shredder can destroy.

Double shaft shredders can process things of different sizes and shapes, including huge, hefty materials as well as smaller, more delicate items.

A double shaft shredder operates by feeding materials into the machine, which are then cut and shredded by the blades on the two parallel shafts.

Double shaft shredders can reduce the volume of waste, making it easier to transport and dispose of. They can also recover valuable resources from materials that are shredded.

E-mail:

Tel:

Address:

Building A, Sanxing Industrial Zone, Zhangjiagang City, Jiangsu Prov, China